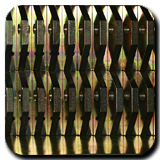

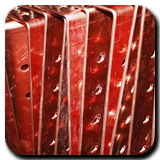

Tin Plating is an electrolytic process that deposits a metallic coating onto the surface of the material. The tin plating process is used extensively to protect both ferrous and nonferrous surfaces. Tin is a useful metal for the food processing industry since it is non-toxic, ductile, and corrosion resistant. It also provides sacrificial protection for copper, nickel and other non-ferrous metals, but not for steel. AMF offers the best looking bright Tin Plate in the market. Lead free tin is a soft metal that provides superior electrical conductivity and corrosion protection. The method of plating is often used to preserve the solderability of under-plated deposits such as copper or nickel. At least 100 grams of contact force is recommended when using Lead free tin in a contact application. Thanks to AMF’s experience in the industry, we can recommend always utilizing a sliding or wiping action during contact engagement in lead free tin plated connector applications. Our lead-free tin deposits meet all. RoHS requirements Lead Free Bright Tin Plating Specifications: ASTM B545, MIL-T-10727 Lead free bright tin exhibits cosmetic reflectivity and is typically used in electrical contact applications such as terminals and switching components that will not be used in solder applications. |

|

||||||||||||||||||||||||||||||||||||||||||