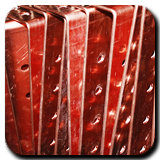

Passivation is the removal of exogenous iron or iron compounds from a stainless steel surface by means of a chemical dissolution. Passivating is accomplished by removing surface contaminates in a chemical bath without significantly affecting the stainless steel. After the parts have been run through the passivation bath, a passive film is spontaneously formed. This passive film improves the corrosion resistance of the stainless steel. Stainless steel passivating improves the condition of part surfaces by dissolving iron that is embedded in the surface during part forming or machining. If the embedded iron is allowed to remain, the iron will corrode and give the appearance of rust spots on the stainless steel Benefits of Stainless Steel Passivation Include: Improve corrosion resistance without plating Superior clean surface Eliminates iron contamination reactions with other materials No discoloration from rust A clean surface prepared for priming and painting |

|

||||||||||||||||||||||||||||||||||||||||||